High Pressure Water Jetting

The purpose of a water pump is to move water not containing suspended solids or particulates. Water pumps handle ground water, potable and salt water. High Pressure water pumps are widely used in water jetting applications.

Water jetting equipment using high pressure water pumps is used to direct high pressure water streams against material to clean or cut it. The streams of water released by water jetting and water blasting equipment is normally 5,000 PSI to 40,000 PSI. In an efficient water jetting system, pressure is vital consideration. Typically, hardened deposits respond better with high pressure water pumps, and softer materials are best removed with lower flows.

Water jetting and water blasting equipment is used for cleaning or demolition of products made of metal, wood, concrete, stone, plastic, glass or other building materials.

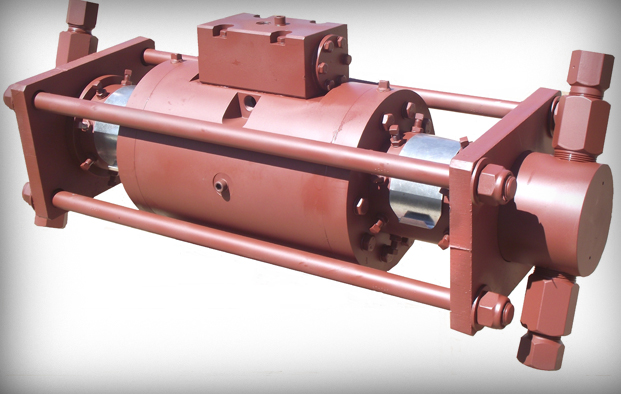

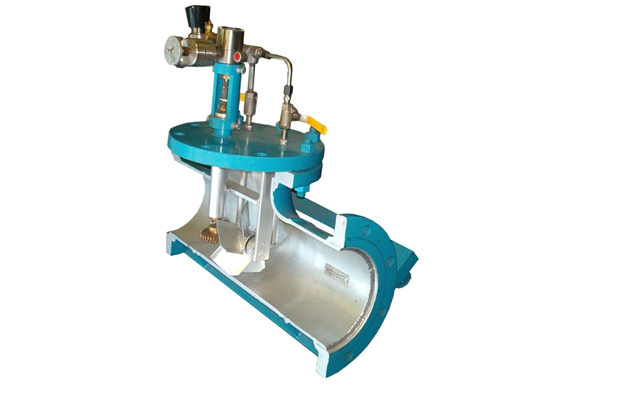

Specific components within a water jetting system include abrasive injectors, pressure generators, blast cabinets or booths, water guns, and water tanks. Abrasive injectors can convert a water jetting system into an abrasive blaster. The injection or metering system controls the amount of abrasive pushed into the air stream. In large systems, the delivery system and injection system may be separate components. Pressure generators increase the pressure of the carrier fluid (water or air). Plunger-type intensifier pumps are commonly used to generate high pressure water for water jet cutting, wet or water abrasive blasting and non-abrasive pressure washing or rinsing.

PRODUCTS:

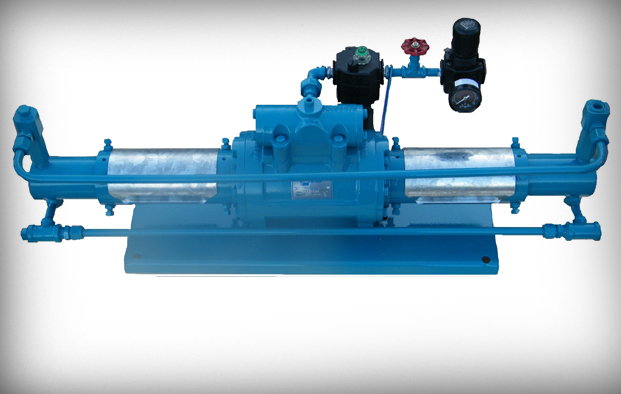

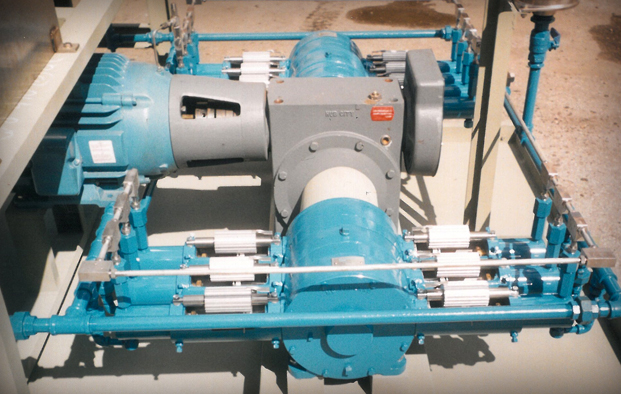

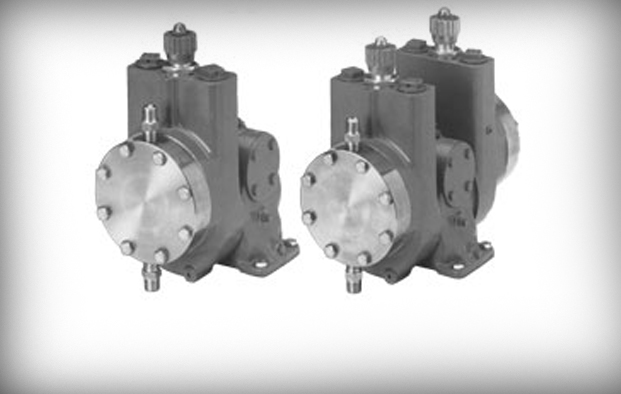

Standard and custom high-pressure Hydro Laser units are built with Tritan triplex or quintuplex pumps. Quintuplex and triplex pumps are positive-displacement reciprocating pumps that are configured with three or five plungers. High pressure water pumps used in high pressure water blasting and water jetting operations.

These hydro laser high-pressure water pumps can be driven by electric motor, diesel, or gasoline engine. A complete system package can be ready to easily take care of your next difficult cleaning job.

Optional Equipment:

Hydro Dump Gun - Constructed Entirely of Stainless Steel.

Jet Tips - Stainless Steel: Two (2) Straight Round Pattern or Two (2) Flat Fan Pattern.

Discharge Gauge.

Relief Valve - Stainless Steel Construction and Adjustable.

Discharge Hose - 50 ft Section

Units are mounted on trucks, trailers, or skids.

A variety of accessories are available to adapt to specialized cleaning requirements. Hoses, Cleaning Guns, Jet Cleaning Heads: Single Orifice, Multi Orifice, Flat Fan, Self-Propelled

Fulfill a multitude of cleaning applications:

Water Jetting, Water-Chemical Cleaning, Water-Sand Cleaning, Water Power Sewer Cleaning & Flushing

Material that can be removed quickly, efficiently and cheaply with a Hydro Laser: Paint, Grease, Sludge, Slage, Core Sand from Castings, Ceramic Residue, Asphalt, Hydrocarbon Residue, Acid Residue, Mineral Build-Up, Rust, Marine Growth, Polymerized Material, Latex, Scale from Steel, Oil, Chemical Residue, and more...