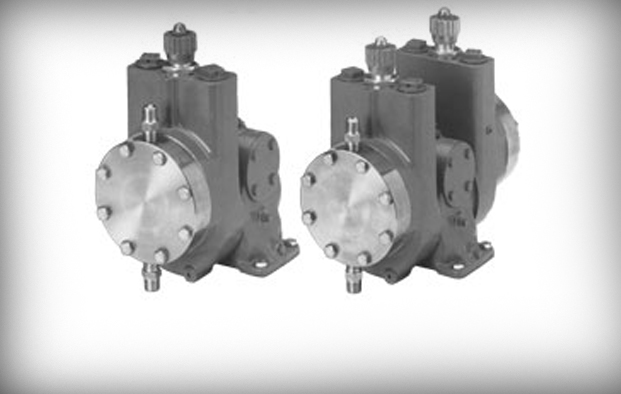

Diaphragm Pumps

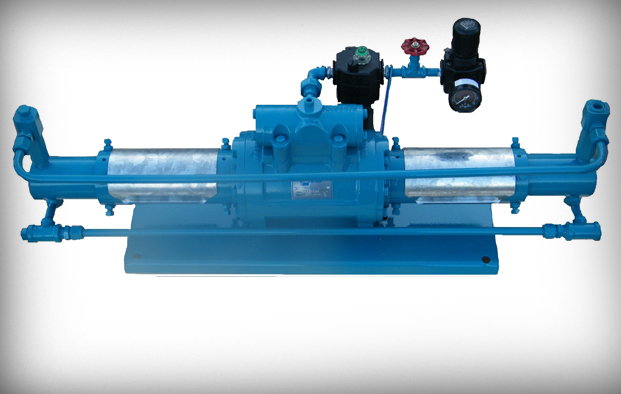

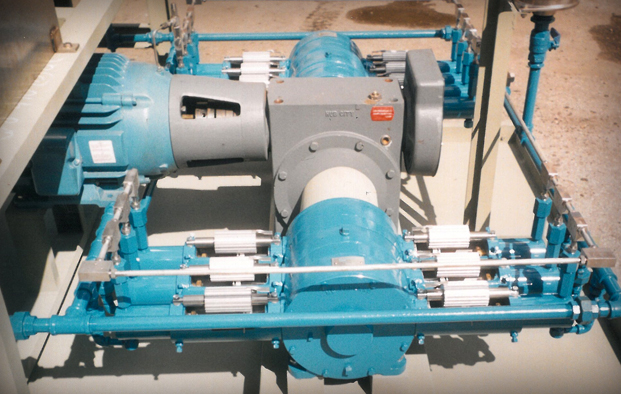

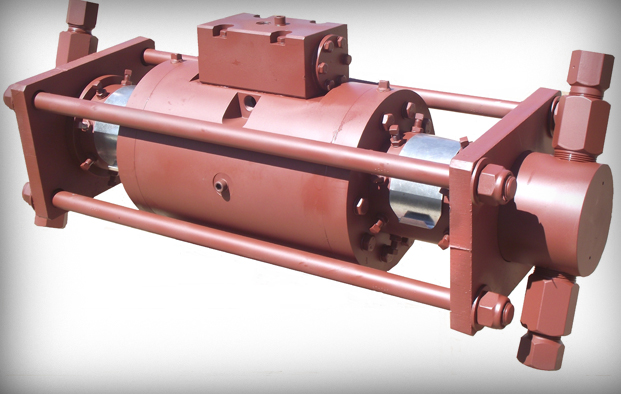

Series Mac-J-5 - Electric Operated, Hydraulically Actuated Diaphragm Metering Pumps (0.8 to 56 GPH)

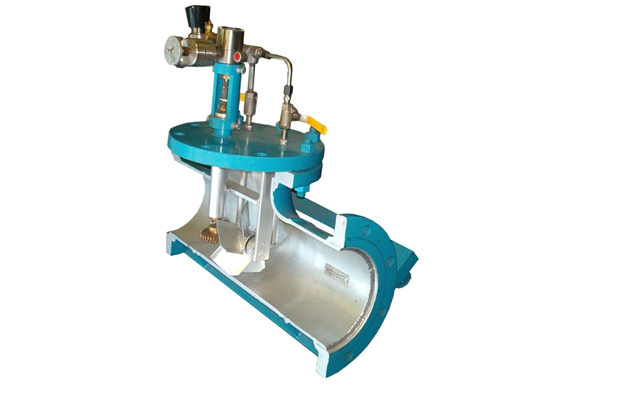

Features/Benefits: Diaphragm pumps are specially designed for accurate, completely leak-proof metering of difficult-to-handle liquids. Separate chambers for hydraulic fluid and gear lubricant make possible the use of the best medium for hydraulic diaphragm pulsing and the best medium for gear lubrication. The results are better pump performance and longer pump life. The Series Mac-J-5 diaphragm pump is available in both simplex and duplex models. Field convertible from simplex to duplex. This diaphragm pumps offers patented, heavy-duty gear reducer system for superior performance. Hydraulically actuated diaphragm minimizes diaphragm fatigue. Built-in hydraulic relief valve protects the pump. Stroke rate easily automated using variable-speed drive.

Capacity is adjustable while pump is running or idle and is adjustable for a turndown ratio of 10:1. Easy-to-read stroke length adjustment dial. This diaphragm pump is available with motor or as bare pump. There are no plunger seals to leak or replace. Oil bath gear lubrication eliminates the maintenance required by packing grease or auxiliary oil systems. Top-mounted lube oil and hydraulic fluid fill ports provide easy access. A single ball check valve, standard on both suction and discharge side of the pump, provides accurate metering and fast response. The valve ball turns with fluid flow, constantly presenting a new face to the seat, and therefore is self- cleaning. This diaphragm pumps provides accuracy of � .5% at steady state.

Materials of Construction: Diaphragm: PTFE, Liquid End: 316 Stainless Steel; PVC; Carpenter Alloy 20; Hastelloy-C

Options: Double ball check valves with or without spring-loaded balls. Double diaphragms with diaphragm rupture detection eliminates process fluid contamination or pump housing damage in the event of a diaphragm rupture.

Motor Options: Electrical, Hydraulic, Air, Belt-driven

Accessories: Safety relief valves, Back pressure valves, Calibration columns, Pulsation dampners

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Volume

based on 90% theoretical maximum. |

Materials of Construction Diaphragm: PTFE Liquid End: 316 Stainless Steel; PVC; Carpenter Alloy 20; Hastelloy-C Options

|

Motor Options

Accessories

|