FLUID SAMPLING SYSTEMS

Crude oil prices necessitate accurate measurement of the BS&W content in oil. Manual sampling methods can result in samples with inaccurate and inconsistent values. Automatic Fluid Sampling Systems are designed to collect continuous, representative samples of oil and BS&W content in oil. Dependable sampling permits accurate determination of the BS&W percentage.

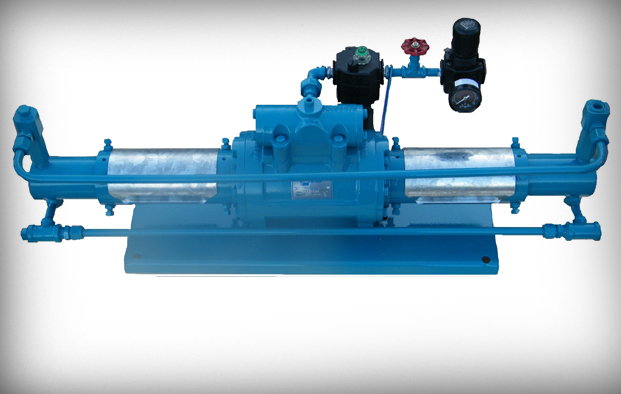

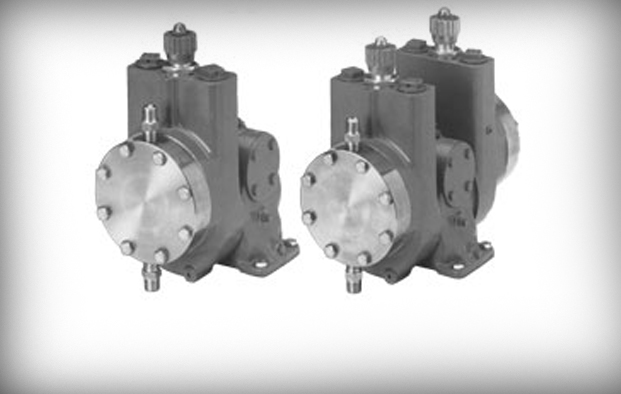

Economy Impulse-Actuated Electric Sampler for Flow Controlled Sampling When Connected to Fluid Meter or Time-Controlled Sampling when Connected to Timer:

This fluid sampling system is engineered for proportionate to flow sampling controlled by a fluid meter or other electrical impulse source and are cost-efficient for crude oil sampling on LACT units. The fluid sampling systems provide flexible installation - Example: sample probe installed in pipeline; line can be powered from meter or timed to solenoid. The Economy Impulse-Actuated Electric Sampler features 0 to 2.5 cubic centimeter-capacity adjustable sample volume regulator; solenoid-operated, explosion-proof three-way sampling valve and fluid inlet pressure regulator. This fluid sampling system is assembled on convenient mounting brackets. Sample volume regulator for larger size samples, from 0 to 10 cubic centimeters, is available. Supplied without pressure regulator and gauge for sampling when line pressure is below 50 pounds per square inch and relatively constant. Three-way solenoid sampling valve can be supplied "normally closed" for sample entry during the "power-on" time of the cycle. Solenoid valves are available for most power characteristics. A complete line of accessories includes McFarland-Tritan, LLC sample probes, sample containers and sample houses. Units can be modified for timer-controlled operations.

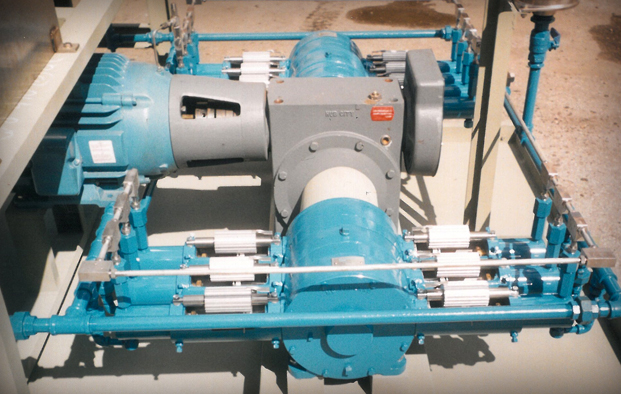

Impulse-Actuated Sampler with Motor-Driven, Slip-Stream Circulating Pump For Flow-Controlled or Time-Controlled Sampling: This fluid sampling system features 1/2 horsepower, 3.5 gallon-per-minute, motor-driven pump for slip-stream circulating along with the standard Economy Sampler components. This Impulse-Actuated Sampler with Motor-Driven, Slip-Stream Circulating Pump For Flow-Controlled or Time-Controlled Sampling circulates fluid through the probe and by the solenoid-sampling valve at adequate velocity to keep water and solids in suspension. This fluid sampler system permits the installation of the sampler remote from the pipeline. Motors are available for most requirements. Installation is similar to the Economy Sampler, but with an added return circulation line and it provides constant-volume sampling when used with a timer. Sampling rates are fixed for any single setting of the timer, but other rates can be obtained by manual resetting of the timer. Can be customized for use with the Economic Sampler.

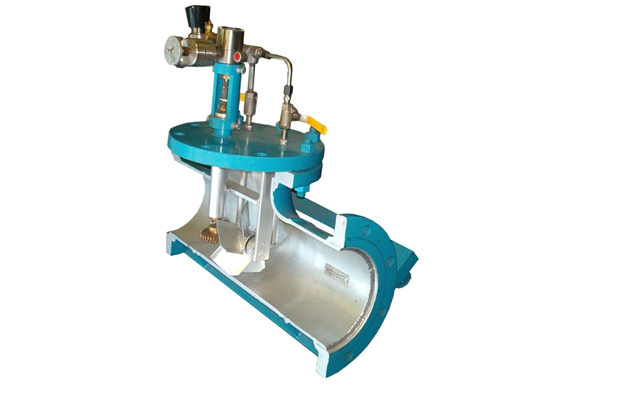

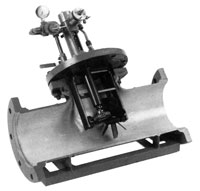

Impeller-Type Sampler For Flow Controlled Sampling (Proportional to Flow):

The Impeller-Type Sampler is installed as an integral part of the pipeline. No outside power or control is required. This Impeller-Type Sampler for flow-controlled sampling features an impeller-driven sampling probe and sample circulation return probe assembled to a blind flange and mounted on a tee-flanged outlet positioned inside pipeline. This system incorporates a rotary sampling valve, McFarland-Tritan, LLC sample volume regulator, inlet probe, return probe piping with shut-off valves and fluid pressure regulator. Rotary sampling valve and fluid-powered impeller control sampling frequency. Adjustable sample volume regulator, from 0 to 2.5 cubic centimeters controls sample size. Rotary sampling valve alternately connects the volume regulator to the probe for filling or to the sample container for emptying. Rotary sample valve, sample volume regulator and probe arrangement are designed to permit passage of sand and BS&W through the sampler without clogging or damage. No check valves are required- eliminating the potential for cutting or plugging. This fluid sampling system will mount on blind flange without tee or on existing pipelines by addition of a saddle, flanged outlet and hot tap. A 24-inch sampler is provided for lines above 24 inches-customer should advise dimension from center of pipeline to face of the sampler-mounting flange. The Impeller-Type Sampler can be supplied mounted on flanged side outlet of a plain end tee, beveled for welding into the pipeline. Flange size and pressure rating are matched to line requirements. Sample volume regulator capacity: 0 to 10 cubic centimeters. Special volume regulators available for large sample sizes. Accessories include sample container, sheet-metal house, companion flanges, and studs and gasket. Fluid flow provides the power and controls the sampling rate. Changes in the sampling rate are directly proportional to changes in the flow rate in the pipeline. Installed in horizontal or vertical lines in accordance with API sampling standards.

Fluid Sampling Systems

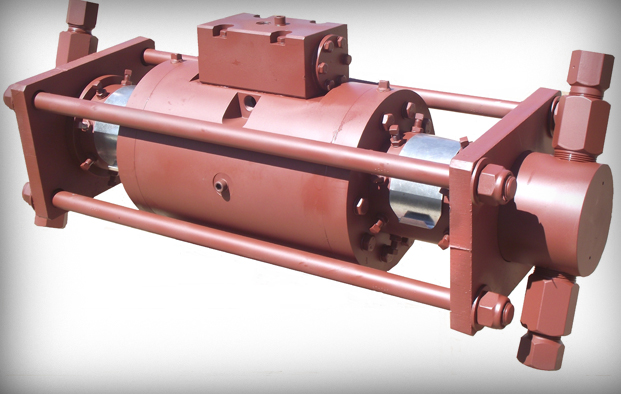

Custom Manufactured Systems: For Your Specific Requirements

Automatic Fluid Sampling Systems

Crude oil prices necessitate accurate measurement of the BS&W content in oil. Manual sampling methods can result in samples with inaccurate and inconsistent values.

- Designed to collect continuous, representative samples of oil and BS&W

Dependable sampling permits accurate determination of the BS&W percentage

Economy Impulse-Actuated Electric Sampler For Flow Controlled Sampling When Connected to Fluid Meter or Time-Controlled Sampling When Connected to Timer

Cost-efficient for crude oil sampling on LACT units

Flexible installation: sample probe installed in pipeline; line can be powered from meter or timed to solenoid

Features 0 to 2.5 cubic centimeter-capacity adjustable sample volume regulator; solenoid-operated, explosion-proof three-way sampling valve and fluid inlet pressure regulator

Assembled on convenient mounting bracket

Sample volume regulator for larger size samples, from 0 to 10 cubic centimeters, is available

Supplied without pressure regulator and gauge for sampling when line pressure is below 50 pounds per square inch and relatively constant

Three-way solenoid sampling valve can be supplied "normally closed" for sample entry during the "power-on" time of the cycle

Solenoid valves are available for most power characteristics

A complete line of accessories includes McFarland-Tritan, LLC sample probes, sample containers and sample houses

Units can be modified for timer-controlled operations

Economy HP for uses up to 1,000 psi. No pressure regulator

Net Weight: 10lbs.

Shipping Cube: 8ft.

Economac Impulse-Actuated Sampler With Motor-Driven, Slip-Stream Circulating Pump For Flow-Controlled or Time-Controlled Sampling

Impeller-Type Sampler For Flow Controlled Sampling (Proportional to Flow)

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

*Standard

6” sampler with end reducers used under 6”

Note: Maximum unit sample volume: 10 cc.

Vapor-Proof, Clear-View Sample Container

Vapor-Proof Clear-View Sample Container features a unique method of vapor-sealing samples removed from the pipeline until removal for analysis. As the container fills, the Hycar synthetic rubber diaphragm is raised by the sample surface, maintaining a vapor seal and indicating the quantity of sample collected. Trouble-free design provides easy and quick dismantling for cleaning. Aluminum bottom-half of the bowl is epoxy coated to prevent water and other substances from sticking to the sides of the container as fluid is withdrawn. Hand-operated circulating pump is standard and will mount on the container's base.

Pipeline Probes For Sampling

Slip-stream, return circulation probes are designed for use with the Economic Sampler. Probes and method of installation can be customized to meet your specific requirements. Diameter of pipeline must be given for probe to be centered on pipeline.

Cone Bottom (Metal) Sample Container

Cone Bottom (Metal) Sample Container features cone-type bottom, gauge glass, hand-operated circulating mixer pump; three-way valve for mixing or-drawing sample from container; and relief valve with a 5- to 13-pound adjustable spring. Container is coated internally and mounted on tripod legs. The sample container provides an easily removable top for cleaning and can be customized for your specific requirements. A hand operated circulating pump will mount directly on the container's base. Standard hand-operated circulating pump can be replaced with optional motor-driven circulating pump. This pump is designed for mixing sample, pumping sample to the transporting container, and pumping surplus sample back into the pumpline. Container can be specified with special protective coating and is available in 5- to 30-gallon capacities.

|  |

| Capacity (Gal.) | Dimensions (in.) | |||||

| A | B | C | D | E | F | |

| 5 | 15 | 7 1/2 | 5 1/2 | 20 | 4 | 6 |

| 10 | 15 | 7 1/2 | 14 | 22 3/4 | 12 1/2 | 5 1/8 |

| 20 | 15 | 7 1/2 | 27 | 22 3/4 | 28 5/8 | 5 1/8 |

| 30 | 19 | 9 1/2 | 25 | 23 1/2 | 23 1/4 | 5 1/8 |